The Best Brim Hard Hat is a sort of protective headgear commonly used in various industries to safeguard individuals from head injuries in hazardous work environments.

It is a variation of the standard hard hat with an extended brim that surrounds the entire circumference of the hat, providing additional protection to the face and neck areas. The full brim design offers enhanced coverage and helps shield the wearer from falling objects, impacts, and sun exposure.

These hard hats are typically made of durable materials such as high-density polyethylene (HDPE) or fiberglass, and they often include a suspension system inside to absorb and distribute impact energy.

Full Brim Hard Hats are widely used in construction, mining, manufacturing, and other industrial settings where head protection is crucial. They not only serve a functional purpose in preventing injuries but also comply with safety regulations and standards set by occupational health and safety organizations.

Related article: Best Construction Hard Hat

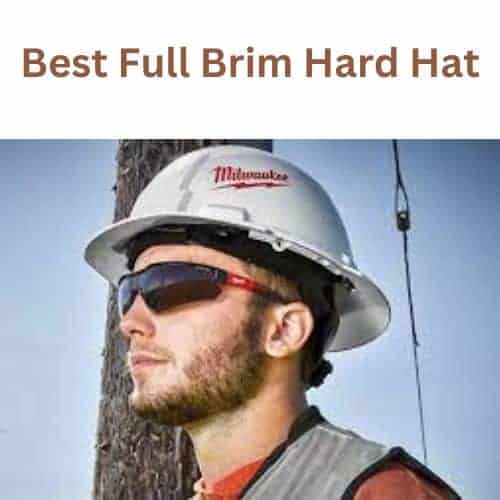

Full Brim Hard Hat

A full-brim hard hat is a type of safety helmet designed to protect the head, neck, and face in various industrial and construction settings. It is an essential piece of personal protective equipment (PPE) to safeguard workers from potential head injuries due to falling objects, electrical hazards, or other workplace dangers.

Key features of a full-brim hard hat include:

Brim: Unlike a regular hard hat with a short brim, a full-brim hard hat has a wider brim that extends all the way around the helmet. This provides additional protection to the neck and face from sun, rain, and falling debris.

Material: Hard hats are typically made of durable materials such as high-density polyethylene (HDPE) or acrylonitrile butadiene styrene (ABS). These materials are chosen for their strength and impact resistance.

Suspension System: The interior of the hard hat is equipped with a suspension system that helps absorb and distribute impact energy. This adds comfort to the wearer and provides a secure fit.

Adjustable Straps: Most hard hats come with adjustable straps to ensure a snug and comfortable fit for different head sizes. This is crucial for the effectiveness of the helmet in protecting the wearer.

Ventilation: Some hard hats feature ventilation holes to improve air circulation and keep the wearer cool during extended periods of use.

Color Options: Hard hats come in various colors, and the choice of color may indicate the worker’s role, company affiliation, or specific safety designation.

Customization: Many full-brim hard hats can be customized with accessories such as face shields, earmuffs, or chin straps to enhance protection and comfort based on specific job requirements.

Employers and workers need to adhere to safety regulations and guidelines when using hard hats, ensuring that they are in good condition and properly maintained. Regular inspections and replacements of damaged hard hats are essential for maintaining their effectiveness in providing protection. Additionally, workers should always wear hard hats in areas where there is a risk of head injury.

How We Tested the Best Full Brim Hard Hats

Research and Selection

Identify a range of full-brim hard hats available in the market based on customer reviews, industry recommendations, and safety standards. Consider factors such as material, design, comfort, and additional features.

Safety Standards Compliance

Ensure that the selected hard hats comply with relevant safety standards (e.g., ANSI/ISEA Z89.1 for head protection in the United States).

Material and Durability Testing

Assess the materials used in the construction of the hard hats for durability and impact resistance. Conduct tests to evaluate the hard hat’s ability to withstand various environmental conditions, such as exposure to sunlight, extreme temperatures, and chemicals.

Impact Resistance Testing

Simulate impact scenarios to evaluate how well the hard hat protects against falling objects. Use standardized methods and instruments to measure impact resistance.

Comfort and Fit Evaluation

Assess the comfort of the hard hat, considering factors like weight, padding, and the adjustability of the suspension system. Ensure that the hard hat provides a secure and comfortable fit for different head sizes.

Ventilation Testing

Evaluate the ventilation system to ensure adequate air circulation, especially in environments with high temperatures.

UV Resistance Testing

Assess the resistance of the hard hat to ultraviolet (UV) radiation, which can degrade materials over time.

Electrical Insulation Testing

If applicable, test the hard hat’s electrical insulation properties to ensure it meets safety requirements for electrical work.

User Feedback and Field Testing

Obtain feedback from actual users, such as construction workers, industrial professionals, or other individuals who may wear full-brim hard hats in their daily work. Conduct field tests to evaluate the performance of the hard hats in real-world conditions.

Comparison and Rating

Compare the performance, features, and user feedback of different hard hat models. Assign ratings or rankings based on the testing results.

Documentation and Reporting

Compile a comprehensive report detailing the testing process, results, and any recommendations. Provide clear documentation on the limitations of the hard hats and any specific use cases they are best suited for.

The 10 Best Full-Brim Hard Hats for 2025

1. MSA (Mine Safety Appliances)

2. Pyramex Safety Products

3. 3M Hard Hat

4. Fibre-Metal by Honeywell

5. ERB Safety

6. Bullard Hard Hat

7. Radians Hard Hat

8. Petzl Hard Hat

9. Klein Tools

10. Jackson Safety (Kimberly-Clark Professional)

When selecting a full-brim hard hat, consider factors such as ANSI/ISEA safety standards compliance, comfort features, ventilation, suspension system, and overall durability.

Additionally, read user reviews to get feedback from individuals who have used the specific hard hat model you’re interested in. Always prioritize safety and choose a hard hat that meets the necessary safety regulations for your industry or workplace.

1. MSA (Mine Safety Appliances)

Mine Safety Appliances, or MSA, is a well-known and reputable company that specializes in providing safety products and equipment for various industries.

The company has a long history, dating back to its founding in 1914 by Thomas Edison and a group of other investors. MSA initially focused on developing safety-related products for miners, which is reflected in its name.

Product Range

MSA offers a wide range of safety products, including but not limited to respiratory protection, head protection (such as hard hats), fall protection, gas detection instruments, thermal imaging cameras, and more.

Global Presence

MSA operates globally and serves customers in numerous industries, including mining, construction, oil and gas, firefighting, military, and general industrial applications.

Innovation

MSA has a reputation for innovation in safety technology. The company invests in research and development to create advanced and reliable safety solutions.

Hard Hats

MSA is well-known for its hard hats, designed to protect against head injuries in various work environments. Their hard hats often meet or exceed safety standards set by organizations like ANSI (American National Standards Institute) and OSHA (Occupational Safety and Health Administration).

Safety Standards

MSA products are typically designed and manufactured to meet or exceed industry safety standards, ensuring that workers are adequately protected in hazardous environments.

Corporate Responsibility

MSA places a strong emphasis on corporate responsibility, sustainability, and environmental stewardship. The company is committed to ethical business practices and social responsibility.

2. Pyramex Safety Products

Pyramex Safety Products is a company that specializes in providing personal protective equipment (PPE) and safety products. The company offers a wide range of safety gear designed to protect workers in various industries.

Some of the key products offered by Pyramex include safety glasses, hearing protection, hard hats, gloves, high-visibility clothing, and respiratory protection.

Safety Glasses

Pyramex is well-known for its safety eyewear, including safety glasses and goggles. These products are designed to protect the eyes from potential hazards such as flying debris, chemicals, and other workplace dangers.

Hearing Protection

Pyramex offers a variety of hearing protection products, including earplugs and earmuffs, to safeguard workers from excessive noise levels.

Hard Hats

The company provides a range of hard hats designed to protect the head from falling objects and impact. These hard hats often meet or exceed safety standards set by organizations such as ANSI (American National Standards Institute).

Gloves

Pyramex offers a selection of gloves for various applications, including cut-resistant gloves, impact-resistant gloves, and general-purpose work gloves. These gloves help protect hands from injuries and provide comfort for extended use.

High-Visibility Clothing

Pyramex manufactures high-visibility clothing, such as vests and shirts, to enhance worker visibility in low-light conditions. This is especially important for individuals working in construction, traffic control, and other industries where visibility is crucial for safety.

Respiratory Protection

The company provides respiratory protection equipment, including disposable respirators and reusable masks, to help protect workers from airborne contaminants.

Safety Helmets and Face Shields

In addition to hard hats, Pyramex offers face shields and accessories to provide additional protection for the face and eyes.

3. 3M Hard Hat

3M manufactures a variety of personal protective equipment (PPE), including hard hats. Hard hats, also known as safety helmets, are designed to protect the wearer’s head from falling objects, impact, and electrical hazards in various work environments. Here are some key points about 3M hard hats:

Head Protection

3M hard hats are designed to protect the wearer’s head in industrial and construction settings. They are an essential piece of personal protective equipment to reduce the risk of head injuries.

Materials and Construction

3M hard hats are typically constructed from durable materials such as high-density polyethylene (HDPE) or other impact-resistant thermoplastics. They often feature a suspension system inside the hat to provide a comfortable fit and to absorb and distribute impact energy.

Customization

Some 3M hard hats offer features for customization, such as adjustable straps, ventilation, and options for attaching accessories like face shields or earmuffs. This allows workers to tailor the hard hat to their specific needs and comfort preferences.

Color Coding

Hard hats often come in various colors, and the color coding may indicate different roles or responsibilities on a worksite. For example, supervisors might wear a different color than general workers, making it easy to identify personnel at a glance.

Safety Standards

3M hard hats, like those of other reputable manufacturers, are designed and tested to meet or exceed safety standards set by organizations such as the Occupational Safety and Health Administration (OSHA) in the United States or the European Safety Standard (EN 397) in Europe.

Product Range

3M offers a range of hard hat models designed for different industries and applications. These may include construction, manufacturing, oil and gas, and more.

Care and Replacement

It’s important to follow proper care and maintenance guidelines for hard hats. They should be inspected regularly for signs of damage and replaced if they have been subjected to a significant impact or have exceeded their recommended service life.

4. Fibre-Metal by Honeywell

Fibre-Metal is a brand of personal protective equipment (PPE) owned by Honeywell. Honeywell is a multinational conglomerate that operates in various industries, including aerospace, building technologies, performance materials and technologies, and safety and productivity solutions.

Fibre-Metal is known for its line of safety products, particularly in the area of head and face protection. The brand produces a variety of safety helmets and face shields designed to protect workers from impact, heat, chemicals, and other occupational hazards. The products are commonly used in industries such as construction, manufacturing, welding, and utilities where head and face protection is crucial.

Some of the features that may be associated with Fibre-Metal products include high-impact resistance, durability, and ergonomic design to ensure comfort during prolonged use. Additionally, the face shields are often designed to provide optical clarity while protecting against various forms of hazards.

5. ERB Safety

ERB Safety is a company that specializes in providing safety products and equipment. They are known for manufacturing a wide range of personal protective equipment (PPE) and safety gear designed to protect workers in various industries. Some of the products offered by ERB Safety include:

Hard Hats: Protective headgear designed to protect against impact and penetration injuries.

Safety Glasses and Goggles: Eye protection to guard against flying particles, chemicals, and other potential hazards.

Hearing Protection: Products such as earmuffs and earplugs prevent hearing damage in noisy environments.

High-Visibility Apparel: Clothing designed with reflective materials to enhance visibility in low-light conditions, promoting safety for workers.

Respiratory Protection: Masks and respirators to protect against inhaling harmful particles or fumes.

Safety Vests: Garments designed for visibility and identification in various work settings.

Fall Protection: Equipment like harnesses and lanyards to prevent falls and protect workers at heights.

6. Bullard Hard Hat

The Bullard Company is known for manufacturing safety equipment, including hard hats. The Bullard hard hat is a type of head protection commonly used in various industries to safeguard workers from head injuries. Bullard hard hats are designed to meet safety standards and provide protection against falling objects, electrical hazards, and other potential dangers in the workplace.

Bullard offers a range of hard hat models with different features to suit various job requirements. Some common features of Bullard hard hats may include adjustable suspension systems, comfortable padding, and durable shell materials. Additionally, some models may be equipped with accessories such as face shields, hearing protection, and communication systems to enhance worker safety and functionality.

7. Radians Hard Hat

Radians is a company that specializes in personal protective equipment (PPE), including safety gear such as hard hats. Hard hats are essential for workers in various industries to protect their heads from falling objects, electrical hazards, and impact injuries.

While I don’t have specific information on all the models and features that Radians offers, I can provide some general information about what you might find in a typical hard hat:

Material

Hard hats are commonly made of durable materials such as high-density polyethylene (HDPE) or acrylonitrile butadiene styrene (ABS) plastic. These materials provide a good balance of strength and weight.

Suspension System

The suspension system inside the hard hat is crucial for providing a comfortable fit and absorbing impact energy. Radians likely incorporate an adjustable suspension system that helps users customize the fit to their head shape.

Ventilation

Some hard hats come with ventilation features to improve airflow and comfort, especially in hot or humid conditions. This is important for preventing overheating and discomfort during extended wear.

Compliance

Radians hard hats are likely designed and tested to meet or exceed safety standards set by organizations such as the Occupational Safety and Health Administration (OSHA) in the United States or similar regulatory bodies in other regions.

Customization

Many hard hats allow for customization, such as adding accessories like face shields, earmuffs, or chin straps to enhance protection based on specific job requirements.

8. Petzl Hard Hat

Petzl is a well-known manufacturer of climbing and caving gear, including helmets. They are particularly recognized for their high-quality equipment designed for outdoor activities, work at height, and rescue operations. However, please note that information may have changed since then.

If Petzl has expanded its product line to include hard hats for industrial or construction use, it would be advisable to check the most recent and specific product information on Petzl’s official website or contact their customer support for the latest details.

Additionally, reviews and feedback from users can provide valuable insights into the performance and features of specific Petzl hard hat models. Always ensure that any safety equipment you choose complies with relevant safety standards in your industry or region.

9. Klein Tools

Hard hats, also known as safety helmets, are designed to protect the head from impact, falling objects, and electrical hazards in construction and industrial settings. These hats typically consist of a hard outer shell made of materials like high-density polyethylene (HDPE) or fiberglass, and an inner suspension system to absorb and distribute impact energy.

Klein Tools is a well-known manufacturer of hand tools and other equipment for professionals in the electrical and telecommunications industries. While Klein Tools is renowned for its high-quality hand tools, it’s essential to note that the availability and specifications of specific products, such as hard hats, may vary.

To get the most accurate and up-to-date information about Klein Tools’ hard hats, I recommend visiting the official Klein Tools website or contacting their customer support. Additionally, you can check with authorized Klein Tools distributors or retailers for detailed product specifications and reviews.

10. Jackson Safety (Kimberly-Clark Professional)

Jackson Safety’s hard hats are designed to provide head protection from falling objects, impact, and electrical hazards. They typically comply with safety standards and regulations established by organizations such as the Occupational Safety and Health Administration (OSHA) in the United States.

Specific features of Jackson Safety hard hats may include:

Material

Hard hats are commonly made from durable materials such as high-density polyethylene (HDPE) or acrylonitrile butadiene styrene (ABS). These materials offer a balance of strength and lightweight.

Suspension System

The interior of the hard hat often includes a suspension system to provide a comfortable and secure fit. This suspension system helps absorb impact energy and provides a gap between the hat’s shell and the wearer’s head.

Adjustability

Many hard hats have an adjustable suspension system or a ratchet-style adjustment to ensure a secure and comfortable fit for various head sizes.

Ventilation

Some hard hats feature ventilation slots or design elements to improve air circulation, enhancing comfort for the wearer during extended use.

Customization

Hard hats may come in various colors, and some models allow for customization, such as adding logos or reflective strips for increased visibility.

Pros and Cons:

A full-brim hard hat, also known as a wide-brim hard hat or a brimmed hard hat, has both advantages and disadvantages. The choice between a full-brim and a cap-style hard hat often depends on the specific needs and preferences of the wearer. Here are some pros and cons of a full-brim hard hat:

Pros:

Enhanced Sun Protection: One of the primary advantages of a full-brim hard hat is the increased protection it provides against sunlight and UV rays. The wide brim shields the face, neck, and ears from direct sunlight, making it suitable for outdoor work in sunny conditions.

Improved Rain Protection: The wider brim also offers better protection against rain, helping to keep the raindrops from running down the neck and into the collar.

Increased Visibility: The larger surface area of the brim can make the wearer more visible, which is particularly beneficial in environments where workers need to be easily seen, enhancing overall safety on the job site.

Accessory Attachment: The extended brim provides more space for attaching accessories such as face shields, earmuffs, and other protective gear without interfering with the wearer’s comfort.

Versatility: Full-brim hard hats are versatile and can be used in various industries, including construction, forestry, mining, and utilities.

Cons:

Heavier Design: Full-brim hard hats can be slightly heavier than their cap-style counterparts due to the larger brim, which may lead to discomfort during extended wear.

Limited Upward Visibility: The extended brim may limit the upward visibility of the wearer, which could be a concern in situations where an unobstructed view of overhead hazards is crucial.

Wind Resistance: In windy conditions, the larger brim can catch the wind, potentially causing the hard hat to shift or be uncomfortable for the wearer.

Cost: Full-brim hard hats can be more expensive than cap-style hard hats, which may be a consideration for budget-conscious individuals or organizations.

Buying Guide

Buying a full-brim hard hat is an important decision, as it involves selecting a piece of safety equipment that can protect you from potential workplace hazards. Here’s a comprehensive buying guide to help you make an informed decision:

1. Safety Standards

Ensure that the full-brim hard hat complies with relevant safety standards, such as ANSI Z89.1 for the United States or CSA Z94.1 for Canada. Look for certification labels to confirm compliance.

2. Material

Full-brim hard hats are typically made of materials like high-density polyethylene (HDPE) or fiberglass. HDPE is lightweight, durable, and offers good impact resistance. Fiberglass may be preferred for its additional strength and resistance to high temperatures.

3. Suspension System

The suspension system is crucial for comfort and impact absorption. Look for an adjustable, comfortable, and secure suspension system that provides a good fit. Options may include ratchet suspension or pin-lock suspension systems.

4. Adjustability

Ensure that the hard hat is adjustable to fit different head sizes comfortably. Some models come with a ratchet system, allowing for easy adjustment with a simple twist.

5. Ventilation

Ventilation can be crucial for comfort, especially in hot and humid conditions. Look for full-brim hard hats with ventilation features like built-in vents or sweat-wicking liners to improve air circulation.

6. Full Brim Design

The full-brim design provides additional protection against sun, rain, and falling debris. Ensure that the brim is wide enough to shield your face and neck adequately.

7. Customization

Some hard hats come with accessory slots that allow you to attach accessories such as face shields, hearing protection, or lights. Check if the hard hat you are considering supports the accessories you may need.

8. Durability

Consider the durability of the hard hat, especially if you work in environments with extreme conditions. Look for resistance to UV rays, chemicals, and high temperatures.

9. Weight

While full-brim hard hats are generally lightweight, it’s still essential to consider the weight, especially if you’ll be wearing them for extended periods. Choose a balance between comfort and protection.

10. Brand Reputation

Opt for reputable brands with a history of producing high-quality safety equipment. Reading reviews and seeking recommendations can also help you make an informed decision.

11. Cost

Price is a factor, but it should not be the sole determinant. Invest in a quality hard hat that meets safety standards and provides the necessary protection for your work environment.

12. Maintenance

Regularly inspect and maintain your hard hat. Clean it according to the manufacturer’s instructions, and replace it if you notice any signs of wear or damage.

Specification

A full-brim hard hat, also known as a wide-brim hard hat or brimmed hard hat, is a type of head protection commonly used in various industrial and construction settings. These hard hats are designed to provide additional protection to the wearer’s face, neck, and ears by featuring a brim that extends beyond the front of the helmet.

Material

Hard hats are typically made from high-density polyethylene (HDPE) or other durable thermoplastics. Some models may have a fiberglass or metal outer shell for added strength.

Brim Size

The brim of a full-brim hard hat extends around the entire circumference of the helmet. Brim size can vary, but it is typically wider than the brim on a standard hard hat.

Suspension System

The suspension system is the inner part of the hard hat that helps absorb and distribute impact energy. It is often adjustable to provide a comfortable and secure fit.

Adjustment Mechanism

Hard hats usually have an adjustable strap or ratchet system to ensure a snug fit on the wearer’s head.

Ventilation

Some models may have ventilation slots or openings to improve airflow and provide comfort during extended wear.

Compliance and Certification

Full-brim hard hats should meet the safety standards and certifications set by relevant regulatory bodies in the region or industry.

Color and Visibility

Hard hats are often available in various colors, and some models may have reflective tape for increased visibility in low-light conditions.

Accessory Slots

Many hard hats have accessory slots that allow users to attach accessories such as face shields, earmuffs, or headlamps.

Weight

The weight of the hard hat is an important consideration for comfort during extended use.

Electrical Insulation

When selecting a full-brim hard hat, it’s crucial to consider the specific safety requirements of the job or industry.

(FAQs)

Q. What is a full-brim hard hat?

A: A full-brim hard hat is a type of safety helmet designed to protect the head, particularly against impact from falling objects, electrical hazards, and other workplace dangers. It features a brim that extends around the helmet, providing additional coverage compared to a standard hard hat.

Q. Why choose a full brim hard hat over a standard one?

A: The full brim design offers more coverage to protect against sun, rain, and falling debris. It also provides a larger surface for attaching accessories such as face shields, earmuffs, and safety glasses.

Q. Are full-brim hard hats suitable for all industries?

A: Yes, full-brim hard hats are suitable for a wide range of industries, including construction, manufacturing, forestry, and utility work. They are versatile and can provide the necessary protection in various working environments.

Q. Can I customize my full-brim hard hat?

A: Some manufacturers offer customization options, such as adding company logos or specific colors. However, it’s essential to check with the manufacturer to ensure that any customization does not compromise the integrity of the hard hat or its compliance with safety standards.

Q. How should I care for and maintain my full-brim hard hat?

A: Regularly inspect your hard hat for any signs of damage, such as cracks, dents, or wear. Clean it with mild soap and water, and avoid using harsh chemicals that could weaken the material. Replace your hard hat if it has sustained a significant impact or if it shows signs of deterioration.

Q. Can I wear a full-brim hard hat backward?

A: No, it is not recommended to wear a full-brim hard hat backward. The brim is designed to protect the face and neck from falling objects and sunlight. Wearing it backward may compromise its effectiveness and could pose a safety risk.

Q. Do full-brim hard hats protect against electrical hazards?

A: Some full-brim hard hats are designed to provide electrical insulation and protection against low-voltage electrical hazards. However, it’s crucial to check the specific electrical protection rating of the hard hat and ensure that it meets the requirements of your work environment.

Final Words

A full-brim hard hat is a crucial piece of personal protective equipment (PPE) designed to provide head protection in various industrial and construction settings. The inclusion of a full brim extends the coverage around the sides of the head, offering additional protection against falling objects, electrical hazards, and exposure to sun and rain.

#HardHatLife #SafetyFirst #ConstructionVibes #FullBrimFam #WorkWearGoals #StaySafeOutThere #HeadgearStyle #JobSiteFashion #HardHatHustle #ConstructionChic #GearUp #ProtectYourNoggin #SafetySquad #OnTheJob #WorkplaceWarrior #ConstructionCrew #HardHatHappiness #ToolTime #BuildingDreams #WorkplaceEssentials #HardHatStyle #SafetySwag #ConstructionLife #HeadsUp #WorkIt #JobSiteReady #HardHatLove #SafetyIsCool #ConstructionZone #GetYourGearOn